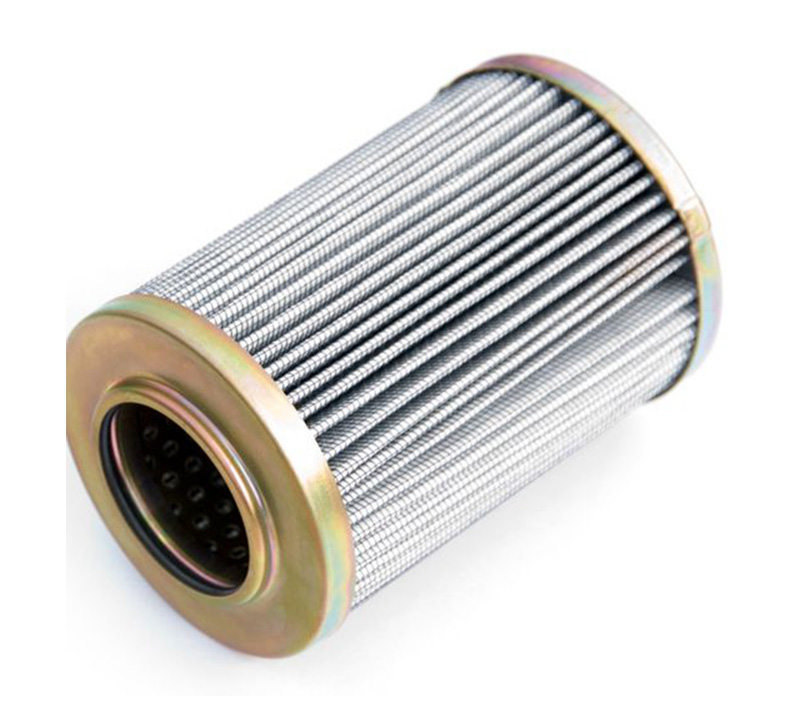

1. Material

* stainless steel wire mesh * plant fiber filter paper

* Inorganic fiber composite filter paper * Epoxy coated wire mesh

Its our advantage ,the support of the filter element is epoxy coated wire mesh , we have produce line for it .

2. Descriptions

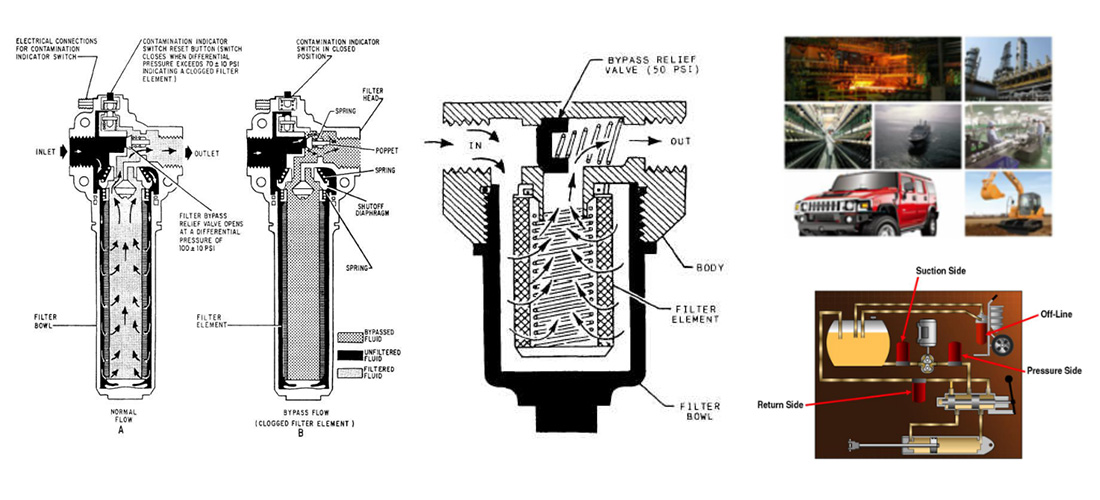

* Structure

(1) Cap (2) Skeleton (3) Filter layer (4) Support layer (5) Sealing element

* Product classification

(1)According to the installation position classification :

a. Oil suction filter b. Return oil filter element c. Pressure line filter

(2)According to the material classification :

a. Inorganic fiber composite filter element b. Paper filter c. Metal mesh filter

* Filter accuracy

Filter element hydraulic pump oil suction pipe : 100 um

An oil outlet of the oil pump on oil pipeline filter hydraulic pump : 10um~15um

pressure duct : 5um / 10um

Note

: The different installation location need different filter accuracy

element , it will affect the life of the product and the normal

operation of the machine . We can provide technical support for

customers

* Working temperature : -10~+135℃

*Processing method

Cutting,

folding, the compressive strength and flexural strength, edge clamp,

assembly, bonding, packaging and high precision must to do bubble test,

special structure or materials need to be cured

3.Function

The

hydraulic oil hydraulic machinery like blood, with the transmission

power, reduce the friction between the components, isolation of the worn

surface, superficial pollutants, oxidation control element surface,

cooling and other functions. The hydraulic components of hydraulic oil

hydraulic filter is a key link.

Solid pollutants, contaminants

outside intrusion, internally generated pollutants, maintenance,

maintenance and maintenance of pollution are sources of pollution. It

will bring serious harm to the hydraulic machinery, hydraulic oil in

high temperature and high pressure in the long-term use of hydraulic

filter, caused by oil spills, reducing the mechanical use of life, thus

increasing the maintenance cost and large production cost.

Because of

this, we must strengthen the control of the hydraulic oil pollution, to

ensure the normal operation of the hydraulic system. We focus on

prevention treatment, such as: the use of ultra filtration device, in

the process of mechanical operation such as: hydraulic professional

manufacturers The oil filter, at any time oil contaminant removal,

long-term to maintain the hydraulic oil in the hydraulic system

cleanliness operation, that nature is to reduce the due to all kinds of

evils caused by oil pollution, produce the effect of prevention, an

increase of the service life of the hydraulic machinery and hydraulic

components, reduces the failure rate of the machinery. In order to save

energy and reduce the cost.

4. Unique advantages (Only our factory can provide)

* In additon to high quality regular product , we can also produce special shaped hydraulic filter element .

* We

have a number of professional R & D professionals in the industry,

so we can design for you free of charge for your filter .

* We have a sound quality management system.

* Professional personnel to track the use of products,do pre sales and after-sales service.

* Products with quality problems, we are free to replace the product

5. Application

*Metallurgy:

used for steel rolling mill, hydraulic system of continuous casting

machine filter and filtration of all kinds of lubrication equipment.

*Petrochemical:

the separation and recovery of products and intermediate products in

the process of refining, chemical production, liquid purification,

magnetic tape, optical disc and photographic film in the manufacture of

purification, oilfield water injection and gas in addition to particle

filter.

*Textile: polyester melt in the drawing process of

purification and uniform filter, air compressor protection filter,

compressed gas of oil removing water.

*Electronics and

pharmaceuticals: reverse osmosis water, de ionized water to be treated

by filtration, wash liquid and glucose pretreatment filter.

*Mechanical

processing equipment: paper machinery, mining machinery, injection

molding machine and large precision machinery lubrication system and

compressed air purification, tobacco processing equipment and spraying

equipment dust recovery filter.

*Railway internal combustion engines and generators: filtration of lubricating oil and oil.

*Automotive engines and construction machinery, ships, trucks with a variety of hydraulic oil filter